Definition of Synthetic Petrol

Synthetic petrol, also known as synthetic gasoline or e-fuel, is a type of liquid fuel produced from non-petroleum sources, such as natural gas, coal, biomass, or even carbon dioxide captured from the air. Unlike conventional petrol, which is derived from crude oil, synthetic petrol is created through chemical processes that can mimic the molecular structure of fossil fuels, making it compatible with existing internal combustion engines.

How Synthetic Petrol is Made

The most common methods for producing synthetic petrol involve the Fischer-Tropsch process or methanol-to-gasoline (MTG) synthesis. Here’s a brief overview of these methods:

- Fischer-Tropsch Process:

- Converts carbon monoxide and hydrogen (known as syngas) into liquid hydrocarbons.

- The syngas can be obtained from various sources, like natural gas, coal, or biomass.

- A catalyst (often iron or cobalt-based) is used to combine the hydrogen and carbon monoxide under high temperatures and pressures, resulting in synthetic fuel.

- Methanol-to-Gasoline (MTG) Process:

- Involves converting methanol into synthetic gasoline.

- Methanol can be produced from syngas derived from natural gas, coal, or renewable sources.

- The process involves dehydration of methanol into dimethyl ether (DME), followed by converting DME into hydrocarbons that form synthetic petrol.

Advantages of Synthetic Petrol

- Reduced Carbon Footprint: If produced using renewable energy and CO₂ captured from the atmosphere, synthetic petrol can be a carbon-neutral fuel.

- Compatibility with Existing Infrastructure: Synthetic petrol can be used in current gasoline engines and distributed using the existing fuel infrastructure.

- Energy Security: Reduces dependence on fossil fuel imports by diversifying energy sources.

Challenges and Considerations

- High Production Cost: Currently, the production of synthetic petrol is more expensive compared to conventional petrol due to the complex processes and the energy required.

- Energy-Intensive: The processes require a significant amount of energy, which can offset the environmental benefits if not sourced from renewables.

- Scalability: Large-scale production of synthetic petrol is still in the early stages, and its widespread adoption depends on technological advancements and cost reductions.

Would you like to explore a specific aspect of synthetic petrol, such as its environmental impact, production methods, or potential future applications?

Eexploration of production methods

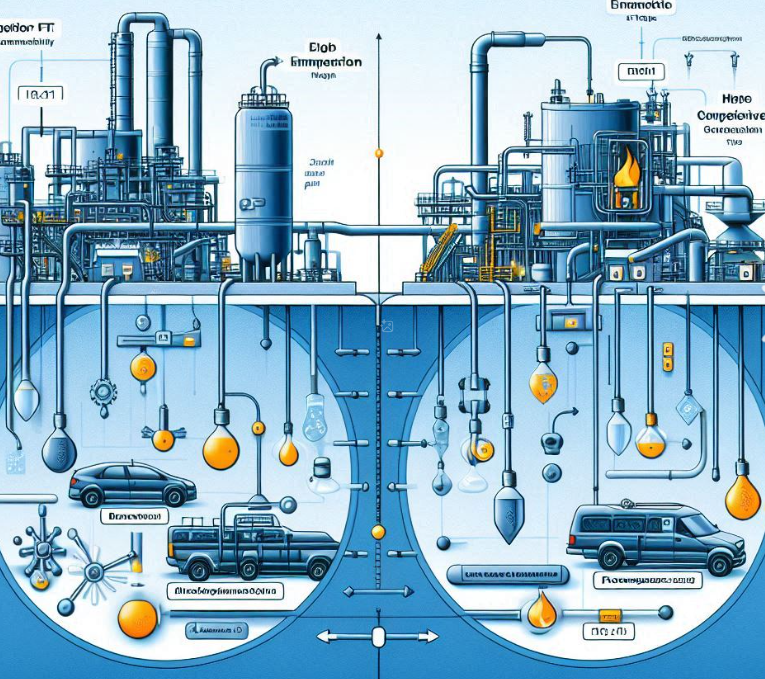

Let’s dive deeper into the production methods for synthetic petrol. The two primary methods are the Fischer-Tropsch (FT) process and the Methanol-to-Gasoline (MTG) synthesis. Each method has unique steps, advantages, and challenges. Here’s a more detailed exploration:

1. Fischer-Tropsch (FT) Process

Overview

The Fischer-Tropsch process is a chemical reaction that converts a mixture of carbon monoxide (CO) and hydrogen (H₂) — known as syngas (synthesis gas) — into liquid hydrocarbons, including synthetic petrol. This process can be applied to various feedstocks, such as coal, natural gas, or biomass.

Steps Involved

- Syngas Production:

- The first step involves producing syngas, which is a mixture of CO and H₂.

- Syngas can be derived from several sources:

- Natural Gas Reforming: Natural gas (methane) is reformed using steam or oxygen to produce syngas.

- Coal Gasification: Coal is heated at high temperatures in the presence of oxygen and steam to produce syngas.

- Biomass Gasification: Organic materials (like agricultural waste) are gasified under controlled conditions to produce syngas.

- Fischer-Tropsch Synthesis:

- The syngas is fed into a reactor where it contacts a metal catalyst (commonly iron or cobalt) at high temperatures (150-300°C) and pressures.

- Under these conditions, the CO and H₂ molecules react on the catalyst’s surface to form longer-chain hydrocarbons, which condense into liquid form. This liquid is then refined into synthetic petrol.

- Product Upgrading and Refining:

- The raw liquid hydrocarbons from the FT reactor are further refined and upgraded to produce a range of fuels, including synthetic petrol, diesel, and jet fuel.

- Refining involves removing impurities, adjusting the carbon chain length, and enhancing the fuel quality to meet specific standards.

Advantages of the FT Process

- Feedstock Flexibility: Can use a wide range of feedstocks (natural gas, coal, biomass), making it adaptable to various geographic and economic contexts.

- High-Quality Fuel: Produces clean-burning synthetic fuels with fewer impurities (e.g., sulfur, aromatics) than conventional petrol.

- Carbon Capture Potential: When combined with carbon capture and storage (CCS), the process can be optimized for reduced CO₂ emissions.

Challenges of the FT Process

- Energy Intensity: Requires a significant amount of energy, especially for syngas production.

- Capital Costs: High initial investment for building FT plants and the necessary infrastructure.

- Carbon Emissions: If fossil fuels (like coal or natural gas) are used as feedstocks without CCS, the process can result in high CO₂ emissions.

2. Methanol-to-Gasoline (MTG) Process

Overview

The Methanol-to-Gasoline (MTG) process converts methanol into hydrocarbons that form synthetic petrol. Methanol can be produced from various feedstocks, such as natural gas, coal, or biomass, through syngas.

Steps Involved

- Methanol Production:

- Methanol is produced from syngas, similar to the FT process.

- Syngas is generated from feedstocks like natural gas, coal, or biomass.

- Conversion to Dimethyl Ether (DME):

- The methanol is first dehydrated to form dimethyl ether (DME).

- This step occurs in a reactor where methanol is exposed to a catalyst, such as γ-alumina, at elevated temperatures (250-400°C).

- DME to Hydrocarbons (MTG Conversion):

- The DME is then further processed in another reactor, where it is exposed to a zeolite catalyst at even higher temperatures (400-500°C).

- Under these conditions, DME molecules are converted into hydrocarbons, primarily in the gasoline range (C5-C12), which can be used as synthetic petrol.

- Product Refining and Blending:

- The resulting hydrocarbons are refined and blended to meet fuel quality standards, removing any remaining impurities and adjusting properties such as octane rating.

Advantages of the MTG Process

- Production of High-Quality Fuel: Produces a high-octane fuel with fewer impurities, leading to cleaner combustion.

- Lower Capital Costs: Generally, requires less capital investment than FT synthesis plants.

- Simpler Chemical Pathway: The process involves fewer steps and lower energy requirements than FT synthesis.

Challenges of the MTG Process

- Feedstock Dependency: Heavily dependent on the availability of methanol, which itself requires energy-intensive production from syngas.

- Carbon Emissions: If methanol is produced from fossil fuels, it can still contribute significantly to CO₂ emissions.

- Scalability Issues: While the process is simpler, large-scale production is still challenging due to the need for significant methanol supplies.

Emerging and Alternative Methods

Beyond these two primary processes, there are several emerging and alternative methods for producing synthetic petrol:

- Power-to-Liquid (PtL) or E-Fuels: Involves using renewable electricity to produce hydrogen via electrolysis and combining it with CO₂ (captured from the air or industrial processes) to create synthetic fuels. This method has the potential for near-zero carbon emissions if powered entirely by renewable energy.

- Biochemical Conversion: Uses biological processes, like fermentation of biomass, to produce alcohols that can be converted into petrol-like fuels.

- Solar Fuel Production: Uses sunlight to drive chemical reactions that convert CO₂ and water into hydrocarbons. This approach is still largely experimental.

Would you like to explore one of these specific methods further, or do you want more details on a particular aspect of the FT or MTG processes?

Let’s explore potential future applications

Exploring the potential future applications of synthetic petrol, we find that this innovative fuel could play a transformative role in several sectors, particularly as the world seeks to reduce its carbon footprint and transition to more sustainable energy sources. Here are some key areas where synthetic petrol could be highly impactful:

1. Decarbonizing the Transportation Sector

The transportation sector, including cars, trucks, airplanes, and ships, is a significant contributor to global carbon emissions. Synthetic petrol offers a potential solution for reducing these emissions, particularly in areas where electrification may not be feasible or practical.

- Aviation:

- The aviation industry is challenging to decarbonize due to the energy density required for long-haul flights. Synthetic petrol, particularly when produced as sustainable aviation fuel (SAF), could provide a drop-in alternative that is compatible with existing jet engines and infrastructure.

- Major airlines and aircraft manufacturers are already investing in synthetic fuels to meet future regulatory requirements and achieve carbon-neutral growth.

- Maritime Shipping:

- Shipping relies heavily on bunker fuels, which are among the most carbon-intensive fuels. Synthetic petrol and other synthetic fuels, such as synthetic diesel and methanol, could replace traditional marine fuels, helping to reduce the carbon footprint of global shipping fleets.

- Synthetic fuels can be used in existing engines with minimal modifications, making them an attractive option for retrofitting older ships.

- Automotive Applications:

- While electric vehicles (EVs) are growing in popularity, there remains a vast number of internal combustion engine (ICE) vehicles on the road. Synthetic petrol can be used in these vehicles without requiring changes to the engine or fueling infrastructure, offering a way to reduce emissions from the existing fleet.

- It could also serve as a transitional fuel in regions where the electrification of transport is slower due to economic or infrastructural challenges.

2. Backup Power Generation and Grid Stability

- Energy Storage and Peak Power Supply:

- Synthetic petrol can be stored easily and used in existing gas turbines for electricity generation, providing a reliable backup power source in cases of grid instability or outages.

- It can be used in peak power plants that operate during high demand periods, ensuring grid reliability, especially in renewable-heavy grids where intermittent sources like solar and wind need balancing.

- Remote and Off-Grid Power Generation:

- For remote areas or islands where renewable energy alone may not be sufficient, synthetic petrol can provide a stable and energy-dense fuel alternative.

- It could support microgrids that combine renewables with liquid fuel storage, providing a flexible and reliable power supply.

3. Industrial Uses

- Chemical Feedstock:

- Synthetic petrol can serve as a base chemical feedstock in various industries. It can be broken down into smaller molecules that are used to produce plastics, synthetic rubbers, and other petrochemical products.

- By using CO₂ captured from the air as a feedstock, the process can create carbon-neutral chemicals, providing a sustainable alternative to traditional petrochemical processes.

- Hydrogen Production:

- Synthetic petrol can be reformed to produce hydrogen. In cases where the hydrogen economy becomes more prevalent, synthetic petrol could act as an interim storage medium for hydrogen before it is released on-demand for fuel cells or other applications.

4. Energy Security and Strategic Reserves

- Diversification of Energy Sources:

- Many countries rely on imported oil, which makes them vulnerable to geopolitical risks and market volatility. Synthetic petrol, produced domestically from local resources (like biomass, renewable energy, or captured CO₂), can enhance energy security by diversifying the energy supply.

- Strategic reserves of synthetic petrol can help stabilize fuel supplies during emergencies or disruptions, providing a reliable backup that can be stored long-term.

5. Recycling and Circular Economy Applications

- Utilization of Industrial CO₂ Emissions:

- Synthetic petrol production can help utilize CO₂ emissions from industrial processes, turning a waste product into a valuable resource. This approach aligns with circular economy principles, where materials are reused and recycled rather than disposed of.

- By capturing CO₂ from power plants, factories, or even directly from the atmosphere, synthetic petrol production can help mitigate emissions from hard-to-abate sectors.

- Waste-to-Fuel Applications:

- Synthetic petrol could be produced from waste biomass, such as agricultural residues or municipal solid waste. This would help address waste management challenges while creating a valuable energy product.

6. Military and Strategic Applications

- Fuel Supply for Defense Operations:

- Military forces rely heavily on liquid fuels for mobility and power. Synthetic petrol could provide a secure, sustainable, and local supply of fuel for military operations, especially in remote or contested areas.

- Its compatibility with existing engines and infrastructure makes it an attractive option for reducing the logistical challenges of fuel supply in defense operations.

- Disaster Relief and Humanitarian Missions:

- In disaster relief scenarios, synthetic petrol can provide an easily transportable and storable energy source for generators, vehicles, and other equipment.

- It can be used in remote areas where other fuels or electricity may not be readily available, supporting emergency operations and humanitarian missions.

7. Transition Fuel for Decarbonizing Hard-to-Electrify Sectors

- Complement to Electrification:

- While many sectors are moving towards electrification, certain areas — like heavy industry, aviation, and shipping — are difficult to electrify due to the high energy density required. Synthetic petrol can serve as a transition fuel in these sectors, providing immediate emissions reductions while longer-term solutions are developed.

- As technology improves and production costs decrease, synthetic petrol could gradually replace fossil fuels in these sectors, bridging the gap towards a fully decarbonized future.

Future Outlook

- Cost Reduction and Scalability:

- Continued advancements in production technology, increased use of renewable energy sources, and economies of scale are expected to lower the costs of synthetic petrol production, making it more competitive with conventional fuels.

- Governments and organizations are beginning to recognize synthetic fuels as part of their long-term energy strategies, which could lead to increased funding, research, and supportive policy frameworks.

- Integration with Renewable Energy:

- Synthetic petrol production can be integrated with renewable energy sources, such as wind and solar, to create a fully renewable supply chain. This integration could further enhance the sustainability of synthetic fuels and drive their adoption across various sectors.

Would you like to explore a particular future application in more detail, or is there another aspect of synthetic petrol that you’re interested in?

Leave a Reply